Industrial Mixers

PerMix Double Cone Mixer

Industrial Powder Mixer Solutions for Homogeneous Blending

PerMix Double Cone Mixers, a type of tumbler mixer, ensure uniform blending by rotating continuously, allowing consistent contact of the materials with the vessel’s interior. This makes them ideal for fast and even mixing of free-flowing powders, granules, and crystals.

With the simplest design among industrial mixers, double cone mixers stand out for their low cost, easy operation, efficient discharge with no residue, fast cleaning, and minimal maintenance.

Double Cone Mixer - Working Principle

Working Principle of Double Cone Blenders: How They Deliver Uniform Blending

Understanding the working principle of Double Cone Blenders is key to appreciating why they are a preferred solution across industries such as pharmaceuticals, food processing, and chemical manufacturing. These tumbler mixers are designed to deliver efficient and homogenous blending of dry powders and granules, making them a versatile choice for consistent granule blending.

The Working Principle of Double Cone Blenders

The double cone blender utilizes a uniquely shaped conical vessel that rotates along a central horizontal axis, gently tumbling materials to achieve uniform mixing without applying excessive shear or heat.

- Tumbling Motion:

- The conical vessel rotates, causing powders and granules to cascade within the chamber.

- This motion promotes even distribution and eliminates dead zones.

- Symmetry for Consistency:

- The symmetrical double-cone design ensures a balanced flow pattern.

- It gently blends fragile materials without degradation or overheating.

- Free-Flowing Design:

- Ideal for free-flowing powders and dry granules.

- The absence of internal agitators makes it suitable for heat-sensitive powders.

- Optional Add-Ons:

- Intensifier Bars: Improve the mixing of fine or cohesive powders.

- Vacuum Capability: Allows for air removal and contamination-free blending.

- Heating & Cooling Jackets: Support temperature-controlled processes.

Advantages of Using Double Cone Mixers

Key Benefits of Using PerMix Double Cone Blenders

PerMix Double Cone Blenders offer a powerful combination of performance, versatility, and value. These advanced powder mixing machines are built to deliver consistent results while meeting the demanding requirements of modern manufacturing environments.

1. Consistent Mixing Performance

- Even Particle Distribution: The double-cone geometry ensures thorough blending by continuously rotating and gently tumbling materials.

- Delicate Handling: Ideal for fragile powders and sensitive granules, preserving product integrity throughout the process.

- Enhanced Add-On Features: Optional intensifier bars can improve mixing of cohesive or fine powders without damaging the product.

2. Adaptability for Varied Applications

- Handles Diverse Powders: Suitable for free-flowing, cohesive, and blended materials with different particle sizes.

- Multi-Process Capabilities: Supports both mixing and vacuum drying when equipped with optional thermal control systems.

- Cross-Industry Compatibility: Widely used in food, chemical, nutraceutical, and pharmaceutical sectors for its reliable performance.

3. Technology-Driven Features

- Vacuum Compatibility: Reduces drying time while improving product quality and density.

- Integrated Thermal Jackets: Enables precise control over temperature-sensitive processes like crystallization or drying.

- Inert Atmosphere Option: Prevents oxidation and allows safe processing of flammable or reactive ingredients.

4. User-Friendly Operation & Maintenance

- Streamlined Material Handling:

- Vacuum-assisted loading minimizes labor and exposure.

- Fast and thorough discharge with options like butterfly valves or tilt-out systems.

- Sanitary Engineering: Mirror-polished interiors and easy-to-clean design promote hygienic processing.

- Low Energy Usage: Optimized for energy efficiency with minimal power requirements.

5. Engineered for Long-Term Use

- Industrial-Grade Materials:

- 316L stainless steel, Hardox, and Hastelloy options ensure durability across challenging applications.

- Titanium construction available for ultra-corrosive environments.

- Explosion-Proof Compliance:

- Certified systems for ATEX and Ex-proof requirements ensure safe operation in hazardous zones.

- Reliable Design: Built to run continuously with minimal wear and maintenance downtime.

6. Customization Options for Specialized Needs

- Integrated Process Controls: Add-ons like PLC/HMI systems and load cells support precision batching and automation.

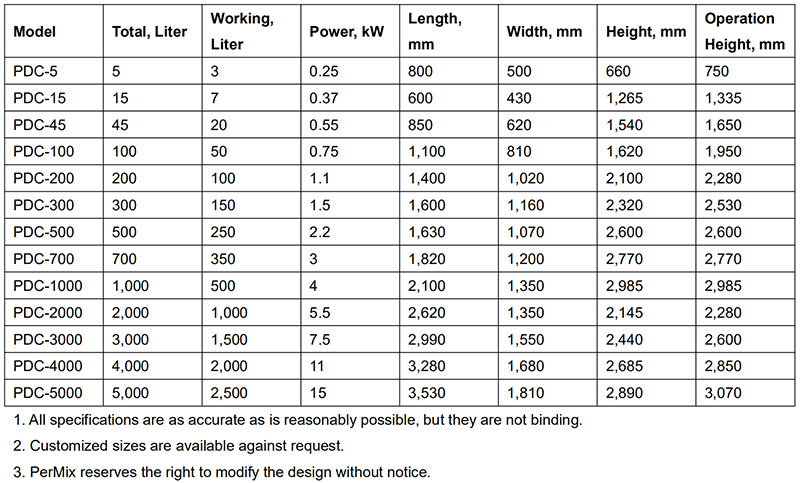

- Scalable Configurations: Available in a wide range of sizes with modular options to fit space and production goals.

- Certifications & Compliance: Meets ASME, GMP, and other international regulatory standards.

7. Cost Efficiency and Value

- Energy Savings: Low operating power reduces utility costs over time.

- Minimized Downtime: Durable design and quick-cleaning features cut production delays.

- All-in-One Capability: Dual functionality for mixing and drying reduces the need for multiple machines.

Why Choose PerMix Double Cone Blenders

PerMix Double Cone Blenders go beyond standard mixing solutions, offering superior flexibility, precision, and value. Whether you’re processing powders for pharmaceuticals, food, chemicals, or cosmetics, our advanced blending systems are engineered to deliver performance that sets the industry standard.

Contact PerMix today to discuss your production needs and discover the right solution for your blending and drying applications.

Features & Options

Advanced Customization Options for PerMix Double Cone Blenders

PerMix offers an extensive range of advanced features for its Double Cone Blenders, ensuring top-tier performance across industries. From explosion-proof safety to handling abrasive and corrosive materials, every configuration is tailored for optimal blending and drying efficiency.

1. Precision Thermal Control with Heating & Cooling Jackets

- ASME-Certified Jackets: Compatible with steam, thermal oil, water, or glycol for precise temperature control.

- Cook & Chill Systems: Designed for food-grade processes requiring rapid heating and cooling transitions.

- High-Pressure Jackets: Ideal for demanding chemical and industrial thermal applications.

Use Cases: Pharmaceutical drying, food ingredient conditioning, and temperature-sensitive chemical reactions.

2. Vacuum Systems for Enhanced Drying & Product Purity

- Moisture Removal: Lowers boiling points for efficient drying of heat-sensitive materials.

- Contamination-Free Environment: Maintains product integrity in pharmaceutical and nutraceutical applications.

- Solvent Recovery: Recaptures solvents during blending processes in chemical industries.

3. Inert Gas Purging Systems

- Oxidation Prevention: Maintains inert environments for reactive powders and sensitive formulations.

- Cryogenic Processing: Enables ultra-low temperature handling of delicate ingredients.

- Advanced Integration: Automated gas flow regulation and synergy with vacuum features for process stability.

4. Flexible Loading & Discharge Configurations

- Vacuum Loading Systems: Ensures efficient and contamination-free material input.

- Manual & Automated Loading: Options include bag dump stations, tote loaders, and drum handling systems.

- Unloading Flexibility: Tilt-out, bottom valve, and integrated screw conveyors tailored to your process needs.

5. Engineered Materials for Harsh and Specialized Environments

- General Use & Sanitary Applications:

- 304 Stainless Steel – Standard-grade material for general-purpose blending.

- 316L Stainless Steel – Offers enhanced corrosion resistance for food and pharmaceutical industries.

- Abrasive Material Handling:

- Hardox Steel – Tough and long-lasting, ideal for abrasive substances like minerals, mortar, and cement.

- Wear-Resistant Linings – Adds durability for prolonged operation with rough or coarse materials.

- Corrosive Environments:

- Hastelloy – Withstands harsh chemicals, acids, and oxidizers.

- Titanium – Exceptional chemical resistance for highly corrosive or reactive processing environments.

- Explosion-Proof & ATEX-Compliant Designs:

- Certified Safety – Meets all ATEX and ExP safety standards for flammable material processing.

- Intrinsically Safe Components – Features spark-resistant construction and fully sealed wiring systems for hazardous zones.

Advantages Of Vacuum Drying Using A Double Cone Mixer

Maximizing Drying Efficiency with Vacuum Double Cone Mixers

Vacuum Double Cone Mixers are transforming industrial drying processes by combining gentle handling with highly efficient moisture removal. This advanced equipment is designed to meet the demands of sensitive, high-purity applications across industries like pharmaceuticals, food, and chemicals.

1. Gentle and Uniform Drying

By creating a vacuum environment, these mixers lower the boiling point of moisture, allowing for low-temperature drying. This protects heat-sensitive materials from degradation while ensuring consistent results across every batch.

2. Efficient Heat Transfer

The rotating double cone design ensures continuous movement and exposure of materials, enhancing heat transfer. The vacuum accelerates moisture evaporation without requiring high temperatures—saving energy and preserving product quality.

3. Faster Drying Times and Cost Savings

Reduced drying time leads to increased production throughput. Faster batch turnover minimizes energy consumption and labor hours, offering a direct cost advantage for high-volume processing environments.

4. Versatility Across Material Types

Vacuum Double Cone Mixers can handle powders, granules, and even sticky or cohesive substances. This versatility makes them an excellent fit for multiple industries requiring consistent drying performance across different product types.

5. Minimal Product Loss

The tumble action ensures all materials are uniformly exposed to the vacuum and heating surface, reducing clumping and uneven drying. This results in higher product recovery and minimal waste.

6. Easy Cleaning and Maintenance

Smooth internal surfaces and accessible design make these mixers easy to clean between batches. Their simplicity reduces downtime and supports GMP or sanitary compliance in regulated environments.

7. Industry Compliance and Safety

PerMix vacuum double cone mixers are available with configurations that meet FDA, GMP, and ATEX standards. This ensures safe operation in pharmaceutical, food-grade, or hazardous processing environments.

Integrating a Vacuum Double Cone Mixer into your process can dramatically improve drying performance, reduce energy use, and enhance product quality. Explore how PerMix can help you unlock superior efficiency in your mixing and drying operations.

Using Double Cone Mixers In High-Performance Thermoplastics Production

Optimized Mixing Solutions for High-Performance Thermoplastics with Double Cone Mixers

As industries like automotive, aerospace, and electronics push the boundaries of material innovation, the need for reliable, high-precision blending is greater than ever. Double Cone Mixers provide the gentle, uniform mixing required for high-performance thermoplastics, delivering consistency and protecting material integrity during processing.

Why Double Cone Mixers Are Ideal for Thermoplastics

Double Cone Mixers use a rotating conical design that creates a slow, tumbling motion—ensuring thorough blending without excessive heat or mechanical stress. This is critical when working with thermoplastics that are sensitive to temperature and shear.

- Gentle Blending: Protects fragile polymers and additives from damage.

- Uniform Distribution: Ensures even dispersion of fillers, stabilizers, and pigments.

- Low Thermal Impact: Prevents overheating or degradation of heat-sensitive materials.

- Built for Abrasive Compounds: Durable materials like Hardox or 316 stainless steel resist wear from fiber-reinforced plastics.

- Scalable Solutions: From pilot-scale to full production, mixers can be tailored to your process.

Applications in Thermoplastic Blending

Double Cone Mixers are well-suited for blending advanced thermoplastics such as:

- PEEK (Polyetheretherketone)

- PPS (Polyphenylene Sulfide)

- PA (Nylon)

- TPE (Thermoplastic Elastomers)

- PC (Polycarbonate)

Whether you’re preparing masterbatches or blending polymers with performance-enhancing additives, Double Cone Mixers ensure precise and repeatable results.

What Sets PerMix Double Cone Mixers Apart

- Material Versatility: Choose from 304/316 stainless steel, Hardox, titanium, and more.

- Custom Integration: Add options like vacuum systems, gas purging, heating & cooling jackets, and load cells.

- Operator-Friendly Design: Easy to clean, maintain, and operate for reduced downtime.

- Engineered Durability: Built to withstand abrasive and high-density compounds.

With over 60 years of innovation, PerMix delivers blending solutions for thermoplastics that prioritize quality, efficiency, and long-term reliability. Our Double Cone Mixers are trusted across industries to maintain material integrity while enhancing productivity.

Ready to optimize your thermoplastic processing? Contact PerMix today to explore customized solutions that meet your exact production goals.

Ready to Build Your Perfect Blender?

Ready to Build Your Perfect Blender?

PerMix’s advanced options empower you to tailor your mixing and drying systems for maximum efficiency, safety, and performance. Whether you’re working with abrasive compounds, corrosive chemicals, or highly sensitive materials, we offer customized engineering to meet your exact needs.

Reach out to our team today and discover how we can design the ideal Double Cone Blender or Vacuum Mixer/Dryer for your process requirements.

PerMix – Where Engineering Meets Innovation to Deliver Superior Mixing Solutions.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.