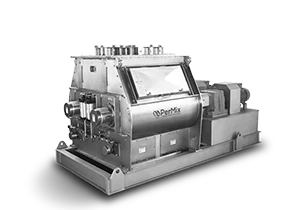

Industrial Mixers

Conical Mixer - High-Quality Mixing with PerMix Conical Mixers

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

The PerMix PNA series Conical Auger Mixer, also known as a Nauta Mixer®, is a batch mixing equipment used widely in applications that require gentle mixing and minimal heat generation without any product distortion.

Because no seals or bearings are exposed in product zone, there is no risk of lubricant contamination. The PerMix PNA series Conical Mixer, part of our powder mixers collection, is featured by its very low energy consumption, low maintenance cost, but high performance of mixing.

A spiral screw (or two, three screws according to specified application) inside of a PerMix PNA series Conical Auger Mixer rotates by its own axle parallel and near the wall of the cone vessel. It lifts the powders around it from the bottom to the top, and then the powder falls down due to the gravity.

At the same time, the spiral screw of the conical mixer rotates around the center of the cone like a planetary, so that the powders in every corner of the cone can be mixed by the screw.

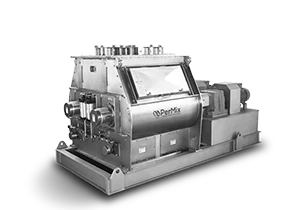

a. Screw Type

We offer single screw, double screw and triple screw to give different mixing intensity.

b. Drive system

Drive system by geared motor, cycloidal reducer, worm reducer, belt or chain transmission, etc.

c. Construction Material and Finish

We are able to offer our PVR Mixers with contact part to be built in Carbon steel, SS304, SS316/316L, Titanium, Duplex stainless steel, Hastelloy, etc. Finish of internal and external finish can be dull polished, 180 grit polished (food grade), or mirror polished. For abrasive materials we offer hardened steel as the contact part.

d. Heating/Cooling jacket

Jacketed trough for heating/cooling operation

e. Vacuum drying & deaerating

The PNA mixer can be designed for vacuum drying & deaerating or for inner pressure working for special applications.

f. Spray nozzle

Liquid can be added into the powder by spray nozzles on the top.ds for the PS series Bottom Entry Mixers. It can be lifted up by a lifting stand (hydraulic or electric), or it can be installed with flange on the top of a tank, or from its side, or at its bottom. For the vacuum or pressurized tank, the mixer must be equipped with a mechanical shaft sealing.

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.