Industrial Mixers

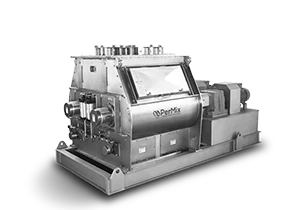

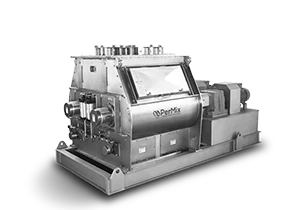

PerMix Ribbon Mixer: High-Quality Ribbon Mixers and Blenders

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

PerMix Ribbon Mixers lead the industry in technology, performance, and value. PerMix Ribbon Mixers are available in two types, Horizontal Ribbon Mixers and Vertical Ribbon Mixers. Both our Horizontal Ribbon Mixers as well as our Vertical Ribbon Mixers are available in capacities from 1 liter to 30,000 liters, and have options that are endless.

The PerMix Ribbon Mixer models, part of our powder mixers collection, are efficient and versatile blending machines for mixing of dry powders, granules and viscous pastes homogeneously. Our ribbon mixers are able to give a satisfying “homogeneity grade” for mixing various jobs due to the special design of a mixing agitator with dual ribbons. Our ribbon mixers are available in size ranges from 1 liter to 30,000 liters and larger if needed.

The PerMix Ribbon Mixer unit consists of one electrical motor, one reduction gear, coupling, and shaft with spiral agitator. The shaft is sealed with bush & PTFE gland housing at both ends.

Materials are loaded from top side, and the discharge is located at the bottom side in the center. The discharge height can be adjusted as per requirement, so that material gets discharged into the container below it without floating dust.

PerMix PRB Ribbon Mixer consists of one electrical motor, one gearbox, and a shaft with double ribbonslocated in a U-shaped vessel.

The external & inner ribbons are designed in such a way that the powder materials are pushed to move from center to the two ends of vessel, and meanwhile from ends to the center; besides, the powder materials are lifted up along the ribbonedges but then drop due to gravity.

In such a three-dimensional way, the total powder can be mixed fast in the vessel. It asks for a short mixing time and relatively low power consumption.

The PerMix PVR series Vertical Ribbon Mixer has a similar appearance with the popular Ribbon Mixer, but stands vertically. It is an efficient and versatile blending machine for batch mixing of free-flowing powders.

The PerMix PVR series Vertical Ribbon Mixer is able to give perfect result for mixing due to the innovative design of an outer spiral type mixing element with an inner reverse direction screw, rotating together into a conical shape trough allowing a perfect discharge of the mixed material.

The construction of PerMix PVR series Vertical Ribbon Mixer is very compact: it consists of a cone vessel with the drive unit on the top and discharge valve at the bottom, and a tapered ribbonmounted on the central shaft. In the cone vessel, there is a central tapered ribbon with very small clearance between its edge and the wall.

The ribbon moves the materials upward along the vessel wall to the top, where the materials then drop by gravity into the center. During this continuous operation, material particles and heat are exchanged quickly which leads to a homogeneous product.

Besides, the material particles are mixed with minimal mechanical and thermal stress, which makes this type of mixer a good solution for fragile and heat sensitive product.

For the latest info on customers, applications, & global installations, visit our blog or visit us on LinkedIn

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.