Industrial Mixers

PerMix 3D Mixer

Gentle 3D Motion for Uniform Powder Mixing

PerMix 3D Mixers, also known as multi-directional powder mixers, are engineered for the uniform blending of powders with different bulk densities and particle sizes.

They also support dry-to-wet and wet-to-wet mixing, offering excellent versatility for a variety of industrial mixing needs.

Introduction

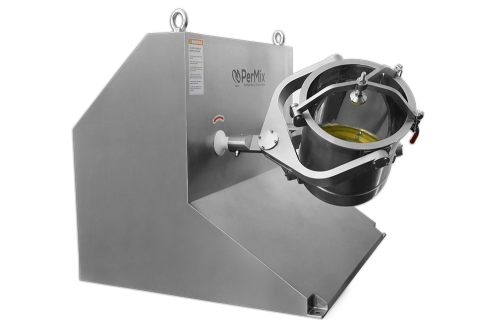

The PerMix 3D Mixer ensures a hygienic, dust-free mixing process by using independent, variable-size containers.

During operation, powders move in multiple directions—horizontally from the center outward and vertically from top to bottom.

This multi-directional mixing method delivers fast, efficient results with reduced power consumption, making it a smart choice for industrial powder mixing.

Working Principle

During the mixing process, the powder moves in random directions—from the center to the edges of the container and simultaneously from top to bottom. This multi-dimensional movement allows the PerMix PTU Series Turbula Blender to achieve uniform results in a short time, with low energy consumption.

Thanks to its gentle mixing action, this industrial mixer is ideal for handling sensitive materials that may degrade under high shear or cause excessive wear due to their abrasive nature.

Construction Material & Finish

We offer our PTU Mixers with contact parts available in a range of high-grade materials, including SS304, SS316/316L, Titanium, Duplex stainless steel, and Hastelloy, to meet diverse processing requirements.

Both internal and external finishes can be customized to suit your specific application and industry standards.

Advantages & Options

- Excellent mixing homogeneity with no dead zones, ensuring consistent results across all batches.

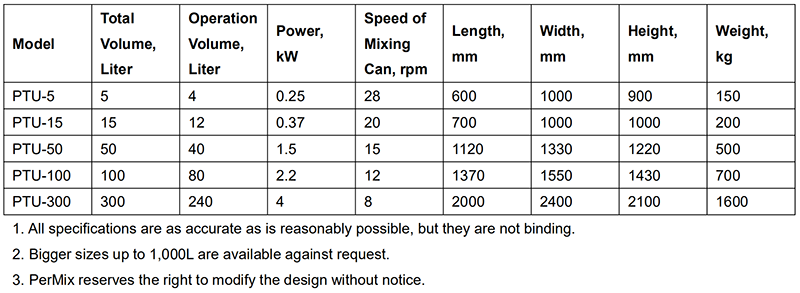

- Available in sizes from 5 to 300 liters total volume to suit various batch requirements.

- Interchangeable drums (for models under PTU-50) enable flexible operation with smaller batches.

- Independent container mixing (optional for small models) minimizes contamination, eliminates emissions, and reduces cleaning effort.

- Designed for complete discharge and easy cleaning, improving operational efficiency.

- Includes a safety cage to protect operators and ensure workplace safety.

- Time-saving container exchange system with fast and simple mounting, ideal for frequent changeovers.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.