Industrial Mixers

PerMix Conical Mixer

Efficient, High-Quality Blending with PerMix Conical Mixers

The PerMix PNA Series Conical Auger Mixer, also known as a Nauta Mixer®, is a type of batch mixer designed for applications requiring gentle, low-shear mixing with minimal heat generation.

It’s ideal for preserving product integrity without causing particle degradation or distortion, making it a reliable choice across industries handling sensitive materials.

PerMix Conical Mixers & Vacuum Conical Mixers/Dryers: A Superior Alternative to Hosokawa®

PerMix Conical and Vacuum Mixers: A Powerful Alternative to Hosokawa

At PerMix, we’re redefining the standards in conical mixing and vacuum drying, combining world-class engineering with innovative technology and reliable performance. Our conical mixers and vacuum conical mixers/dryers offer a powerful alternative to Hosokawa—delivering greater efficiency, enhanced customization, and exceptional value without compromising quality.

With decades of experience in designing mixing and drying equipment for the pharmaceutical, food, chemical, nutraceutical, and cosmetic industries, PerMix has earned a global reputation for outperforming competitors like Hosokawa. That’s why manufacturers worldwide trust us as their go-to partner for high-performance industrial mixing solutions.

🔹 Why Choose PerMix Over Hosokawa?

1️⃣ Advanced Engineering & Superior Mixing Efficiency

PerMix conical mixers and vacuum conical mixers/dryers are engineered with advanced technology to deliver consistent, homogeneous mixing of powders, granules, and liquids—even in the most demanding industrial applications.

- Handles Segregative & Abrasive Materials with Ease: Achieves uniform blending, even with hard-to-mix or abrasive ingredients.

- Optimized Mixing Geometry: Ensures even distribution and reduces processing time.

- Gentle Mixing for Fragile Materials: Ideal for heat-sensitive, fragile, or shear-sensitive products.

✅ PerMix consistently outperforms Hosokawa in energy efficiency, durability, and long-term reliability—making it the smarter choice for manufacturers worldwide.

2️⃣ Customizable Features for Every Application

Unlike Hosokawa, PerMix conical mixers and vacuum conical dryers are built with unmatched customization capabilities to meet the specific needs of your industrial mixing and drying processes.

- Vacuum Mixing & Drying: Precise control over temperature and pressure for moisture-sensitive materials.

- Heating & Cooling Jackets: Maintain thermal consistency for heat-sensitive applications.

- Material Construction Options: Choose from 304/316 stainless steel, Hastelloy, Hardox, or titanium for corrosive, abrasive, or sanitary applications.

- Optional Add-Ons:

- Load Cells for precision weighing and dosing

- PLC/HMI Controls for automation and recipe management

- Gas Purging for inert atmosphere mixing

- Condensate Recovery Systems for energy efficiency

✅ PerMix’s customizable design delivers flexibility and functionality Hosokawa can’t match.

3️⃣ Versatility Across Industries

PerMix conical mixers and vacuum conical mixers/dryers serve a wide range of industries with regulatory-compliant performance.

- Pharmaceutical: GMP-compliant systems for API powders, excipients, and granules. Meets FDA, cGMP, and global standards.

- Food & Beverage: Hygienic, sanitary designs for spices, dairy powders, and sensitive ingredients.

- Chemical & Specialty Materials: Built for corrosive and abrasive materials with Hardox and Hastelloy. ATEX-certified options available.

- Cosmetics & Nutraceuticals: Precise powder blending and vacuum drying to protect active ingredients.

✅ PerMix is trusted across industries to deliver tailored mixing and drying solutions with efficiency and quality.

4️⃣ Better Value Without Compromising Quality

PerMix conical mixers and vacuum conical dryers offer premium performance and engineering at a better value than Hosokawa.

- Extended Warranties and industry-leading customer support

- Faster Lead Times for quicker production starts

- Custom-Engineered Solutions without the premium price tag

✅ With PerMix, you get greater flexibility, performance, and ROI.

5️⃣ Innovation in Mixing Technology

PerMix leads the industry in mixing technology innovation, giving manufacturers a competitive edge.

- Dual Screw Option: Increases mixing efficiency and reduces process time.

- Modular Design: Easily upgrade to vacuum drying, automation, or thermal control.

- Energy-Efficient Engineering: Smart motor systems reduce consumption while maintaining performance.

✅ Our innovation helps you scale with confidence and sustainability.

🔹 Applications of PerMix Conical Mixers & Vacuum Conical Mixers/Dryers

- Mixing Heat-Sensitive Powders: Gentle, low-shear blending prevents thermal degradation.

- Vacuum Drying: Fast, uniform drying that protects product quality in sensitive formulations.

- Abrasive Material Handling: Built with Hardox for wear resistance and extended service life.

- Multi-Component Blending: Accurate, homogeneous mixing of complex powder and granule combinations.

✅ PerMix conical mixers and vacuum conical dryers meet the highest standards for mixing performance, reliability, and product integrity.

🔹 Why PerMix Is the Smarter Choice Over Hosokawa

When it comes to industrial mixers and vacuum conical dryers, PerMix is the clear leader. We deliver better performance, customization, and value—backed by decades of experience.

- Proven Engineering Expertise: Decades of innovation in mixing and drying equipment

- Tailored Solutions: From powder mixers to vacuum dryers, built to your specs

- Comprehensive Support: From planning to installation

- Durable Construction: Hastelloy, Hardox, stainless steel, and more

- Better ROI: High performance at a lower cost

🔹 Ready to Elevate Your Mixing Performance?

PerMix is a global leader in conical mixing and vacuum drying solutions. Our conical mixers and vacuum conical mixers/dryers deliver unmatched efficiency, long-term durability, and cutting-edge innovation—outperforming Hosokawa at a more competitive price point.

📩 Contact us today to discover how PerMix can help you streamline your production, reduce costs, and achieve superior mixing results with confidence.

Working Principle of PerMix Conical Mixers & Vacuum Conical Mixers/Dryers

Working Principle of PerMix Conical Mixers & Vacuum Conical Mixers/Dryers

PerMix Conical Mixers and Vacuum Conical Mixers/Dryers are engineered for precision mixing, homogeneous blending, and efficient vacuum drying. Utilizing gentle tumbling motion with axial-radial mixing, the innovative conical vessel design ensures optimal material flow, prevents dead zones, and minimizes heat buildup—ideal for fragile, heat-sensitive, or segregative materials.

PerMix mixers offer customizable features such as vacuum integration, heating and cooling jackets, and high-speed choppers, delivering versatile mixing solutions for the pharmaceutical, food processing, chemical, nutraceutical, and cosmetic industries.

🔹 Key Components & Their Roles

1️⃣ Conical Vessel for Optimal Mixing & Flow

🔹 The conical shape naturally guides materials downward, ensuring a uniform mixing process.

🔹 Prevents material stagnation and dead zones for batch sizes from small to large.

🔹 Enables complete discharge and reduces material retention and waste.

✅ Why It Matters: Promotes gentle, efficient mixing without overheating or degradation.

2️⃣ Agitator Screw with Planetary Motion

🔹 The central screw rotates on its axis while orbiting the cone’s inner wall.

🔹 Moves materials vertically and radially to ensure homogeneous mixing.

🔹 Suitable for powders, granules, pastes, and liquids.

✅ Why It Matters: Guarantees uniform particle distribution with no segregation.

3️⃣ Vacuum System for Low-Temperature Drying

🔹 Lowers the boiling point of moisture for fast, low-temperature drying.

🔹 Ideal for pharmaceutical powders, nutraceuticals, and specialty chemicals.

🔹 Removes trapped air and enhances product quality.

✅ Why It Matters: Reduces drying time, boosts stability, and prevents oxidation.

4️⃣ Heating & Cooling Jackets for Thermal Control

🔹 Enables precise thermal regulation using steam, water, or thermal oil.

🔹 Ideal for temperature-sensitive processes like crystallization and drying.

🔹 Enhances moisture evaporation and prevents overheating.

✅ Why It Matters: Ensures safe and efficient thermal management of products.

5️⃣ High-Speed Chopper Blades

🔹 Breaks lumps and agglomerates for a uniform final product.

🔹 Essential for wet coating, granulation, and dispersing sticky materials.

🔹 Adjustable speed and blade configuration for specific needs.

✅ Why It Matters: Improves powder homogeneity and flowability.

🔹 Step-by-Step Mixing & Drying Process

1️⃣ Loading the Vessel

🔹 Materials enter the conical vessel, optimizing space and preventing product loss.

✅ Why It Matters: Reduces dust, enhances ingredient dispersion, and maintains batch integrity.

2️⃣ Agitation & Mixing Phase

🔹 The central screw lifts materials as gravity pulls them down, forming a continuous loop.

🔹 Axial-radial motion ensures uniform blending without excess shear.

✅ Why It Matters: Delivers a homogeneous mix and prevents segregation.

3️⃣ Vacuum Drying Process

🔹 Vacuum reduces moisture boiling point, speeding up low-temperature drying.

🔹 Heating jacket enhances drying efficiency.

🔹 Vapor removal allows solvent recovery.

✅ Why It Matters: Maintains product purity and accelerates processing.

4️⃣ Final Product Discharge

🔹 Conical shape directs flow to the outlet for full discharge.

🔹 No product retention—reducing waste and cleanup.

✅ Why It Matters: Improves yield and ensures efficient batch turnover.

🔹 Advantages of PerMix’s Conical Mixer Working Principle

- Gentle, Efficient Mixing: Ideal for fragile, heat-sensitive powders.

- Homogeneous Blending: Eliminates ingredient segregation.

- Fast Vacuum Drying: Reduces processing time and maintains product integrity.

- Customizable Control: Add heating, cooling, choppers, or vacuum systems.

- Hygienic Design: Complies with GMP, FDA, and sanitary standards.

✅ PerMix Conical Mixers deliver reliable performance for precision-focused industries.

🔹 Industries Benefiting from PerMix Conical Mixers

- Pharmaceuticals: Mixing APIs, excipients, and sensitive compounds.

- Food & Beverage: Processing spices, dairy powders, and flavors.

- Chemicals: Blending corrosive or specialty powders and catalysts.

- Cosmetics & Nutraceuticals: Homogenizing herbal extracts and actives.

- Powder Coatings & Advanced Materials: Ensuring uniformity in specialty formulations.

🔹 Why Choose PerMix for Conical Mixing & Drying?

- Advanced Engineering: Built with cutting-edge design expertise.

- Customizable Systems: Tailored for your specific process requirements.

- Superior Efficiency: Low energy use with high output.

- Durable Construction: Made from 316 stainless steel, Hastelloy, Hardox, or titanium.

- Regulatory Compliance: Meets FDA, GMP, ATEX, and sanitary standards.

- Turnkey Support: Full installation, automation, and training provided.

🔹 Get the Perfect Conical Mixer for Your Process

Looking for a high-performance conical mixer or vacuum conical dryer? PerMix has the ideal solution for your production needs.

📩 Contact us today for a customized system and expert consultation! 🚀

Difference Between Single Screw and Double Screw in Conical Mixers

Difference Between Single Screw and Double Screw in Conical Mixers

When selecting a PerMix Conical Mixer, understanding the key differences between single screw mixers and double screw mixers is critical for optimizing your production process. Each configuration offers unique benefits depending on batch size, material properties, and processing goals.

Single Screw Conical Mixer

Overview: A single screw conical mixer features one vertical screw agitator that rotates on its own axis while orbiting along the conical vessel wall. This configuration is highly effective for general-purpose applications and ensures consistent, homogeneous mixing of powders, granules, and liquids.

- Simplicity in Design: Fewer moving parts reduce maintenance needs and simplify cleaning.

- Cost-Effective: Lower upfront investment due to reduced mechanical complexity.

- Ideal for Standard Applications: Efficiently handles a wide range of materials in small to medium batches.

- Compact & Energy-Efficient: Requires less space and power compared to double screw models.

Limitations:

- May have longer mixing times for large batches.

- Less effective with low-density or floating materials, requiring longer mixing duration for full homogeneity.

Double Screw Conical Mixer

Overview: The double screw conical mixer uses two vertical screws that both rotate and orbit within the vessel. This dual action increases mixing intensity, making it ideal for high-throughput production and difficult-to-mix materials.

- High Efficiency: Delivers faster mixing cycles and improved homogeneity, especially for large volumes.

- Superior Handling of Low-Density or Fragile Powders: Minimizes segregation and enhances particle integration.

- Greater Versatility: Suitable for complex processes such as coating, wet granulation, or viscous blending.

Limitations:

- Higher initial cost due to increased mechanical components.

- Greater maintenance needs with more moving parts.

- Higher energy consumption than single screw models.

When to Choose Each Configuration

| Criteria | Single Screw | Double Screw |

|---|---|---|

| Batch Size | Small to Medium | Medium to Large |

| Mixing Time | Moderate | Faster |

| Material Type | Standard or uniform-density | Low-density, segregative, fragile |

| Application Complexity | Basic Mixing | Advanced Coating & Blending |

| Budget | Cost-efficient | Higher initial investment |

Conclusion: Tailored Mixing Solutions by PerMix

At PerMix, we manufacture both single screw and double screw conical mixers to meet diverse processing requirements. Whether your priority is simplicity and affordability or advanced performance and flexibility, PerMix delivers reliable, high-efficiency mixing solutions engineered for success.

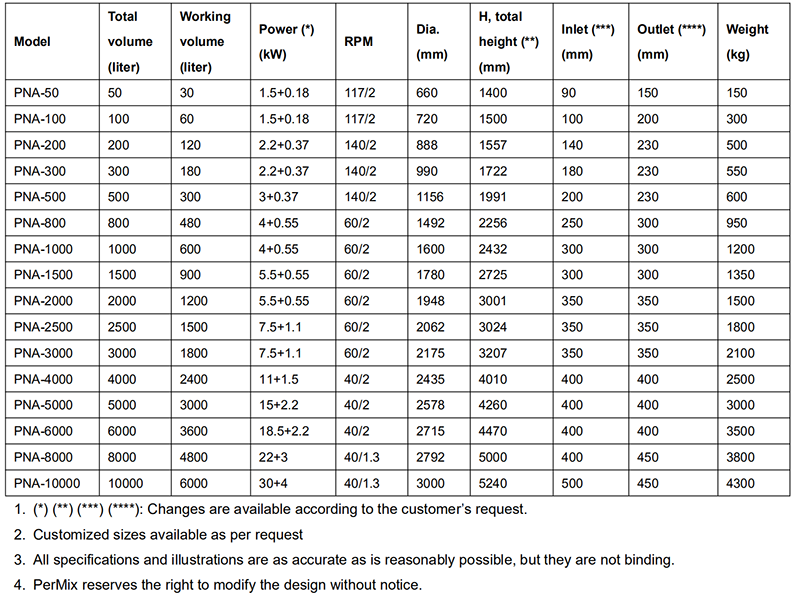

Specifications

Advantages & Options

Available Options for PerMix Conical Mixers & Vacuum Conical Mixers/Dryers

PerMix conical mixers and vacuum conical mixers/dryers are designed with flexibility and performance in mind. Our extensive list of configuration options ensures you get the exact solution tailored to your

process, materials, and industry standards.

Material of Construction

- 304 Stainless Steel: Standard grade with excellent corrosion resistance.

- 316/316L Stainless Steel: Ideal for pharmaceutical, food, and high-purity chemical applications.

- Hastelloy: Engineered for highly corrosive environments.

- Hardox: Abrasion-resistant steel for tough and abrasive powders.

- Titanium: Specialized option for ultra-corrosive or reactive materials.

- Carbon Steel: Budget-friendly option for general-purpose use.

Agitator & Mixing Options

- Single Screw: Efficient solution for most standard applications.

- Double Screw: Ideal for complex materials, large batches, or low-density powders.

- High-Speed Chopper Blades: Breaks down lumps and agglomerates during mixing.

- Liquid Injection Nozzles: Precise addition of binders, flavors, or additives.

Thermal Control Options

- Heating & Cooling Jackets: Steam, water, or thermal oil circulation for temperature control.

- Cryogenic Cooling: Specialized low-temperature mixing for sensitive materials.]

Vacuum System Enhancements

- Mild Vacuum: Suitable for most drying applications.

- High Vacuum: Designed for ultra-sensitive and low-pressure drying needs.

- Condensate Recovery: Recycles vapors, supporting energy efficiency and environmental compliance.

Loading & Discharge Solutions

- Vacuum Loading: Streamlined, dust-free material input system.

- Load Cells: Integrated weighing for accurate batch processing.

- Pneumatic Discharge: Automated unloading system for efficiency.

- Butterfly & Sanitary Valves: Hygienic and durable options for controlled product discharge.

Automation & Control Systems

- PLC/HMI Interface: Full automation with programmable recipes and process control.

- Remote Monitoring: Real-time oversight and diagnostics from any location.

- Explosion-Proof Panels: Certified safety systems for hazardous applications.

Hygienic & Sanitary Design

- CIP (Clean-in-Place): Integrated cleaning systems for fast, residue-free sanitation.

- Mirror-Polished Surfaces: Easy to clean and resistant to contamination buildup.

- Sanitary Seals & Gaskets: Prevent leakage and ensure clean operation.

Gas Purge Options

- Inert Gas Purging: For processing oxygen-sensitive or reactive materials.

- Nitrogen Purging: Reduces oxidation and extends product shelf life.

Additional Customization Options

- Explosion-Proof Design: Safe operation for flammable and volatile processes.

- Insulated Jackets: Minimizes energy loss and improves temperature control.

- Mobile Skid-Mounted Units: Portable setups for flexible deployment.

- Vibration Dampening Mounts: Low-noise, low-vibration performance for sensitive environments.

Why Choose PerMix?

PerMix provides the most configurable conical mixers and vacuum conical mixers/dryers in the industry. Our options are engineered to meet your exact needs—whether you require extreme durability,

fine-tuned temperature control, or smart automation.

📩 Contact us today to build your perfect conical mixer and discover how PerMix can streamline your production process.

Industries & Applications for PerMix Conical Mixers

Industries & Applications for PerMix Conical Mixers

PerMix conical mixers and vacuum conical mixers/dryers are trusted across industries for their exceptional performance, gentle mixing action, and ability to handle a wide range of materials and process

requirements. Their robust, customizable designs make them the go-to solution for manufacturers worldwide.

Pharmaceutical Industry

- Mixing of powders and granules for tablets and capsules

- Vacuum drying of heat-sensitive APIs and intermediates

- Powder coating with active pharmaceutical ingredients

- Scalable from R&D labs to full-scale production lines

Food & Beverage Industry

- Blending spices, flavors, and seasonings

- Combining powdered ingredients for baking or beverage mixes

- Drying delicate food powders, such as dairy or protein ingredients

- Formulating nutritional drink powders and supplements

Nutraceuticals & Dietary Supplements

- Homogeneous mixing of botanical powders for tablets or capsules

- Handling sensitive materials like herbal extracts and probiotics

- Consistent blending of supplements including protein and fiber powders

Chemical Industry

- Mixing fine powders, resins, and catalysts

- Vacuum drying of chemical formulations to preserve properties

- Blending pigments and additives for coatings and plastics

- Durable construction options (Hardox, Hastelloy) for corrosive materials

Cosmetics & Personal Care

- Uniform blending of powders for blush, foundation, and skincare

- Gentle handling of delicate materials like mica and clay

- Vacuum drying of specialty powders for cosmetic use

Powder Coatings & Pigments

- Blending pigments, fillers, and binders for coatings and paints

- Ensuring color uniformity and consistency in final products

Aerospace & Defense

- Mixing lightweight powders for composite materials

- Vacuum processing of sensitive materials for precision components

Construction Materials

- Blending dry powders for grouts, adhesives, and mortars

- Mixing lightweight aggregates and innovative building materials

Energy Storage & Battery Industry

- Mixing powders used in battery components and electrodes

- Vacuum drying under controlled environments

Agricultural Products

- Blending fertilizers, pesticides, and agrochemicals

- Mixing seed coatings and fine powder soil conditioners

Plastics & Polymers

- Mixing masterbatch powders and additives

- Vacuum drying of polymers and heat-sensitive plastic compounds

Mining & Metals

- Blending abrasive metal powders and alloys

- Durable construction ideal for metallurgy and additive manufacturing

Environmental Applications

- Mixing powders used in water treatment and filtration

- Processing specialty chemicals for environmental cleanup

Why PerMix Conical Mixers Are Trusted Across Industries

- Versatile Functionality: Capable of mixing, blending, drying, and coating in one system

- Tailored Designs: Configurable sizes, materials, and control options to meet industry demands

- Sanitary Construction: Hygienic finishes and designs that meet GMP, FDA, and food-grade standards

- Durability & Reliability: Built to handle corrosive and abrasive materials with long-lasting performance

Explore the Right Mixer for Your Industry

From pharmaceuticals and food processing to chemical and battery materials, PerMix conical mixers and vacuum conical mixers/dryers offer unmatched performance, hygiene, and reliability.

📩 Contact our team today to find out how we can support your industry-specific mixing needs with a tailored solution!