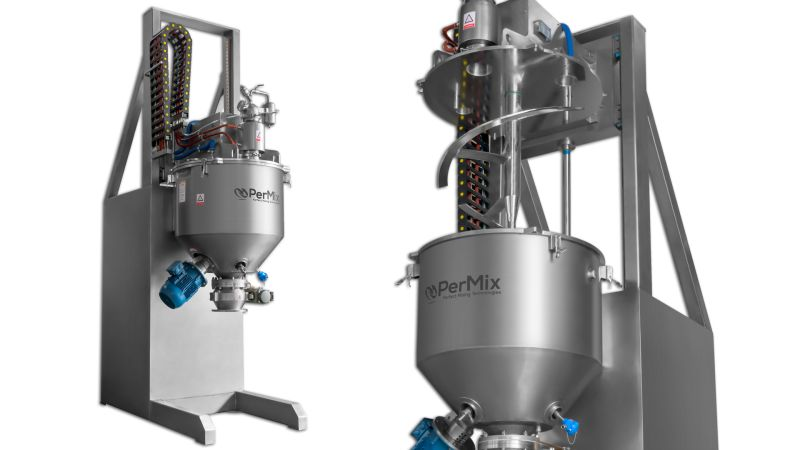

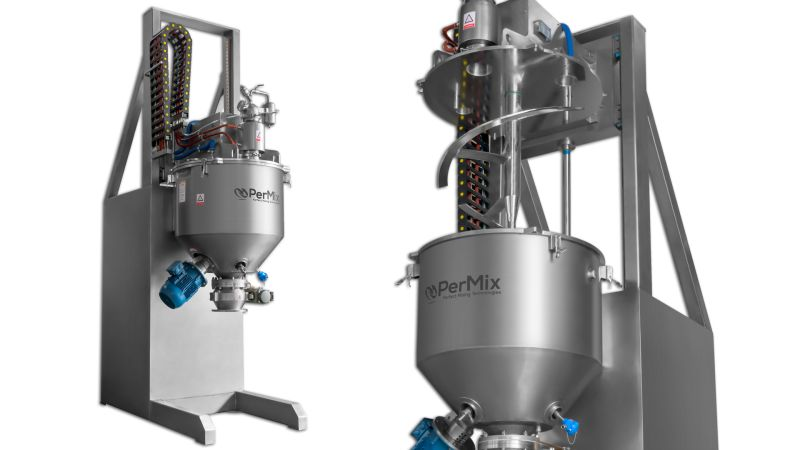

Industrial Mixers

PerMix News & Updates

How Internal Pressure Ratings Dictate Shell Thickness On ASME Pressure Vessels

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) provides guidelines and standards for the design, construction, inspection, testing, and certification of pressure vessels. Internal pressure ratings play a crucial role in determining the shell thickness of ASME pressure vessels. The following is an overview of how internal pressure ratings dictate shell thickness:

ASME Code Requirements:

The ASME BPVC provides specific rules and formulas for determining the required shell thickness of pressure vessels based on various factors, including material properties, design conditions, and loading conditions.

Basic Equation:

The basic equation used to calculate the required shell thickness (t) for cylindrical vessels under internal pressure is derived from the formula for hoop stress (circumferential stress). The equation is as follows:

P⋅D/(2⋅S)+t=C

where:

P is the internal design pressure

D is the inside diameter of the vessel

S is the allowable stress of the material at the design temperature,

t is the required shell thickness,

C is a corrosion allowance (an additional thickness to account for potential corrosion).

Factor of Safety:

The ASME Code incorporates a factor of safety to ensure that the pressure vessel can safely operate under various conditions. The factor of safety is typically applied to the material’s yield strength to determine the allowable stress (S).

Material Properties:

The material properties, such as yield strength and tensile strength, are critical in determining the allowable stress. ASME provides specific tables and guidelines for different materials.

Design Conditions:

The design conditions include the internal pressure, external pressure (if applicable), temperature, and other factors that affect the vessel’s integrity. These conditions are considered in the determination of the required thickness.

Corrosion Allowance:

A corrosion allowance is added to the calculated thickness to account for potential corrosion over the vessel’s service life. The corrosion allowance is typically specified by the engineer and is added to the calculated thickness as a safety margin.

Special Considerations:

In some cases, additional considerations such as nozzle loads, attachments, and openings may require specific analyses and adjustments to the shell thickness.

It’s important to note that the ASME Code provides different equations for different geometries (e.g., cylindrical, spherical, and conical vessels) and considers various loading conditions. Engineers must follow these guidelines and perform the necessary calculations to ensure the pressure vessel’s safety and compliance with applicable standards. Additionally, inspections and non-destructive testing may be required to verify the integrity of the vessel during its service life.

Come see the PerMIx difference at www.permixmixers.com

hashtag#permix #mixers #mixing #asme #industrialmixers #pressurevessels #vacuum