Industrial Mixers

High-Quality Plow Mixers - Discover the Best Plow Mixer for Your Product Needs

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

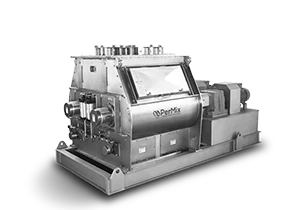

PerMix Plow Mixers lead the industry in technology, performance, and value. PerMix Plow Mixers are available in two types, Horizontal Plow Mixers and Horizontal Plow Mixer / Dryers. Both our Plow Mixers as well as our Plow Mixer / Dryers are available in capacities from 1 liter to 30,000 liters, and have options that are endless

PerMix Plow Mixers, part of our powder mixers collection, are high-efficiency mixers that provide a low/medium shear effect on ingredients when aggressively mixing. Plow mixers are one of the most diverse mixers available as they can be used for blending dry, powdery, granular, fibrous, and moist solids and liquids together with pasty products up to and including highly viscous products. For a less aggressive mixing type with better shearing and resizing effect, see our Paddle Mixer models

Along with being very diverse because of the products/ingredients they can mix, the plow mixer is also very versatile in regards to different processes needed, such as compounding, fine mixing, dispersing, suspending, emulsifying, deaerating, tempering, accelerating chemical or physical reactions, granulating, breaking down agglomerating & more…

PerMix plow mixers are available in numerous configurations, including:

• Horizontal Plow Mixers & Mixers/Dryers

The PerMix Plow Mixers unit consists of one electrical motor, one reduction gear, coupling, and shaft with an agitation that has plow liked shaped attachments that collide with ingredients causing a multi-directional response that mixes products quickly. The shaft of the plow mixer is sealed with bush & PTFE gland housing at both ends.

Materials are loaded from the top side of the plow mixer, and the discharge is located at the bottom side in the center or end, depending on production needs, either batch type or continuous. The discharge height can be adjusted as per requirement, so that material gets discharged into the container below it without floating dust.

PerMix Plow Mixers consist of one electrical motor, one gearbox, and a shaft with plows located in a O-shaped vessel.

The plows are designed in such a way that the powder materials are guided to move from the two ends of vessel to the center, and meanwhile from center to both ends, and over, until batch is mixed thoroughly.

In addition Plow Mixers also lift the ingredients into the air, mixing them in a “fluidized zone” then allow them to drop back down. In such a three-dimensional way, the total powder can be mixed fast in the vessel. It asks for a short mixing time and relatively low power consumption.

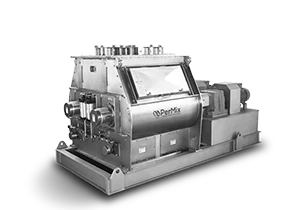

The PerMix Horizontal Plow Mixer / Dryers have the same mixing principle as our Horizontal Plow Mixersbut add the ability to add an external jacket that allows for heating & cooling of products inside the mixer while mixing.

The heating & cooling allows for precision control in temperatures and aids in the drying process. It can also be used to control chemical reactions that may take place during mixing. In addition to adding a jacket, the Plow Mixer / Dryers can also be equipped with internal vacuum. Theses features all allow the PerMix Plow Mixer / Dryers to remain versatile & efficient mixing solutions.

The PerMix Hybrid Plow Mixer / Dryers have the same mixing principle as our Horizontal Plow Mixers & Plow Mixer / Dryers but add the ability for the operator to change agitation type with ease, switching from paddle to plow, or even segmented ribbon.

Plow Mixer Powder Mixing Configurations:

Food flavoring/additives, Sponge/cake mixes, Cosmetics, Pharmaceuticals, Cement, Powdered rubber.

Plow Mixer Paste Mixing Configurations:

Biscuit creams, dough, PVC pastes, Car body fillers/putties, Sugar/marzipan paste, Toiletry pastes, Tile adhesives, and grouts.

Plow Mixer Mixing Of Wet Slurries:

Filter cake re-slurrying, dough, Fiberglass resin dough putty.

Wet granulation, Liquid coating of powders and granules, Fat and oil incorporation, Vacuum drying, Hot air drying.

For the latest info on customers, applications, & global installations, visit our blog or visit us on LinkedIn

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.