Industrial Mixers

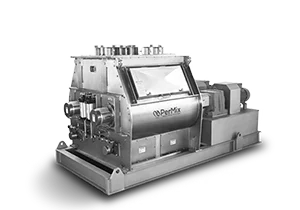

PerMix Ribbon Mixer

High-Quality Ribbon Mixers and Blenders

PerMix Ribbon Mixers set the standard for innovation, efficiency, and value. Available in both horizontal and vertical configurations, our mixers range from 1 to 30,000 liters and come with a wide array of customizable features to suit any processing requirement.

Ribbon Mixers

🔹 PerMix Ribbon Mixers: Precision, Performance, and Versatility

PerMix is a global innovator in industrial mixing solutions, offering advanced ribbon mixers tailored for industries such as food, pharmaceuticals, chemicals, and construction. Whether you need a horizontal ribbon mixer, vertical ribbon mixer, or a vacuum ribbon mixer/dryer, PerMix delivers efficient, durable, and customizable systems engineered for long-term performance.

🔹 Types of Ribbon Mixers

- ✅ Horizontal Ribbon Mixers: Designed for high-efficiency blending of powders, granules, and pastes with precision ribbon agitators. Perfect for fast, uniform batch processing.

- ✅ Vertical Ribbon Mixers: A space-saving solution ideal for gentle blending. These mixers ensure consistent results without damaging sensitive ingredients—commonly used in nutraceuticals and specialty chemicals.

- ✅ Vacuum Ribbon Mixers/Dryers: Combine vacuum drying and mixing in one system, reducing moisture content while protecting product integrity—ideal for pharmaceutical, nutraceutical, and food applications.

🔹 Engineered Construction Options

- ✅ Sanitary Designs: Built with polished 304/316 stainless steel and CIP-ready features to meet stringent hygiene standards in pharmaceutical and food industries.

- ✅ Explosion-Proof & ATEX Compliance: Engineered for safety in hazardous environments with certified motors and controls, suitable for chemical and petrochemical applications.

- ✅ Heavy-Duty Construction: Available in Hardox, Hastelloy, or titanium for abrasive and corrosive processing—ideal for mortar, adhesives, and specialty chemicals.

🔹 Industries That Trust PerMix

- ✅ Food & Beverage: Blending spices, baking mixes, proteins, and infused powders.

- ✅ Pharmaceuticals & Nutraceuticals: Precision powder blending, vacuum drying, and sanitary mixing.

- ✅ Chemical Processing: Built to handle corrosive compounds and complex formulations.

- ✅ Construction Materials: Rugged mixing for industrial powders, mortar, and adhesives.

🔹 Why Choose PerMix Ribbon Mixers?

- ✅ Innovative Engineering: Smart mixer design for faster, more uniform mixing cycles.

- ✅ Custom Configuration: Fully customizable with heating/cooling jackets, spray bars, and discharge options.

- ✅ Versatile Performance: Engineered to support vacuum mixing, wet granulation, and powder induction.

- ✅ Global Reliability: Trusted worldwide across demanding industries for quality and consistency.

- ✅ Cost-Effective Solutions: Delivering premium performance without the premium price.

Ready to upgrade your mixing process with a ribbon mixer that meets your exact specifications?

Contact PerMix today to explore our full range of industrial mixers and get started with a customized solution built to perform.

Working Principle

🔹 How Do Ribbon Mixers Work?

A ribbon mixer is a highly efficient industrial mixer designed to blend powders, granules, and light pastes into a consistent, uniform mixture. Known for their operational reliability and performance, ribbon mixers are widely used in food, pharmaceutical, chemical, and construction material industries.

🔹 The Working Mechanism of a Ribbon Mixer

Ribbon mixers consist of a horizontal or vertical trough equipped with a central shaft and helical ribbons. These ribbons rotate in opposing directions, generating a fluid, efficient mixing cycle that ensures even material distribution.

- ✅ Counterflow Motion: Outer and inner ribbons move ingredients in opposite directions for balanced, thorough mixing.

- ✅ Continuous Folding & Lifting: Promotes uniform blending by constantly circulating the material within the mixer.

🔹 Consistent Material Flow

- ✅ No Dead Zones: Engineered to keep all materials in motion, eliminating stagnant areas.

- ✅ Optimized Mixing Speed: Delivers efficient blending for dry or slightly moist materials.

🔹 Enhanced Blending Efficiency

- ✅ Handles Diverse Materials: Effective for powders, granules, and light paste formulations.

- ✅ Prevents Segregation: Dual-ribbon motion ensures ingredients of varying density are blended seamlessly.

🔹 Key Components of a Ribbon Mixer

- ✅ Mixing Trough: Available in horizontal or vertical formats; constructed from 304/316SS, Hardox, Hastelloy, or titanium based on application.

- ✅ Helical Ribbon Agitator: Features double-layer ribbons to create opposing flow paths for optimal mixing.

- ✅ Drive System: Powered by robust motors, available in standard or ATEX/EXP configurations.

- ✅ Discharge Valve: Quick-release options such as butterfly valves, slide gates, or pneumatic discharges.

🔹 Applications of Ribbon Mixers

- ✅ Dry Powder Blending: Used for spices, flours, chemical powders, and nutritional blends.

- ✅ Powder-Liquid Integration: Enables efficient mixing of liquids into dry base materials.

- ✅ Moist Mixing: Capable of handling slightly cohesive or moist powders.

- ✅ Vacuum Mixing & Drying: Ribbon mixers with vacuum features offer drying, mixing, and cooling in one unit.

🔹 Advantages of Ribbon Mixers

- ✅ Uniform Mixing: Counter-rotating ribbons ensure homogeneity in every batch.

- ✅ Highly Versatile: Suitable for powders, granules, and moisture-sensitive ingredients.

- ✅ Fully Customizable: Options include vacuum systems, thermal jackets, and specialty material construction.

- ✅ Scalable Solutions: Offered in sizes ranging from lab-scale to full-scale industrial mixers.

🔹 Industries That Rely on Ribbon Mixers

- ✅ Food & Beverage: Perfect for spices, baking blends, plant proteins, and supplements.

- ✅ Pharmaceuticals: Blends powders for tablets, capsules, and nutraceutical products.

- ✅ Chemical Processing: Ensures consistency for additives, granules, and specialty compounds.

- ✅ Construction Materials: Durable enough for mortar, cement, and industrial coatings.

🔹 Why Choose PerMix Ribbon Mixers?

PerMix combines innovation, precision, and global expertise to deliver ribbon mixers that exceed industry standards. Our ribbon mixers offer customizable performance, advanced engineering, and reliable results batch after batch.

📩 Get in touch with PerMix today to discuss the best ribbon mixer solution for your application needs!

Installation & Set Up

The PerMix PRB Ribbon Mixer is engineered for straightforward installation and quick integration into your production line. Designed with efficiency and simplicity in mind, the unit arrives as a complete system, including an electric motor, gearbox, and a central shaft equipped with dual ribbons, all housed within a durable U-shaped mixing vessel.

- ✅ Plug-and-Play Design: Minimal on-site assembly is required—simply position, connect to power, and you’re ready to begin operations.

- ✅ Efficient Layout: The compact, floor-mounted design makes it easy to install in both new and existing facilities with limited space.

- ✅ Fast Commissioning: Once installed, the double-ribbon agitator delivers three-dimensional mixing action, reducing setup and calibration time.

As materials circulate between the center and ends while being lifted and dropped by the ribbons, uniform blending is achieved quickly with low energy consumption. The PerMix ribbon mixer is ideal for industries requiring fast, consistent mixing—from pharmaceuticals and food processing to chemical manufacturing.

Advantages of Using a Vertical Ribbon Mixer Versus a Horizontal Ribbon Mixer

🔹 Choosing the Right Ribbon Mixer: Vertical vs. Horizontal

Selecting the right ribbon mixer depends on your production needs, facility layout, and product characteristics. PerMix offers both vertical ribbon mixers and horizontal ribbon mixers, each engineered to meet specific blending requirements across the food, pharmaceutical, chemical, and nutraceutical industries.

🔹 Benefits of Vertical Ribbon Mixers

- ✅ Compact Footprint: Ideal for space-limited facilities with a tall vertical clearance.

- ✅ Gentle Blending: Low-shear agitation preserves the integrity of delicate or friable materials.

- ✅ Sanitary Design: Easy to clean with fewer components and optional Clean-In-Place (CIP) system.

- ✅ Efficient for Smaller Batches: Conical bottom enables full discharge and reduces residue.

- ✅ Flexible Engineering: Options include vacuum integration, thermal jackets, and multiple material choices like 304SS, 316SS, or Hastelloy.

🔹 Advantages of Horizontal Ribbon Mixers

- ✅ Rapid Mixing Cycles: Designed for high-speed, high-capacity processing.

- ✅ Best for Large Batches: Common in food, chemical, and construction material production lines.

- ✅ Extensive Customization: Supports features like spray nozzles, heating/cooling, and ATEX-compliant components.

- ✅ Broad Material Compatibility: Efficiently handles powders, granules, pastes, and moisture-sensitive formulations.

🔹 Which Mixer Should You Choose?

- ✅ Vertical Ribbon Mixer: Ideal for gentle, low-volume processing in compact spaces.

- ✅ Horizontal Ribbon Mixer: Perfect for large-scale, high-speed applications with customizable features.

Need help determining the best fit? Contact PerMix for expert guidance and tailored mixing solutions that match your unique processing needs.

PerMix Vertical Ribbon Mixer Working Principle

🔹 How a Vertical Ribbon Mixer Works

A vertical ribbon mixer is designed to deliver efficient, uniform blending of powders, granules, and light pastes while maximizing space utilization. Its unique upright configuration and helical ribbon agitation make it an excellent choice for gentle, yet thorough mixing in various industries, from food and pharmaceuticals to chemicals and nutraceuticals.

🔹 Understanding the Mixing Process

- ✅ Helical Ribbon Mixing Mechanism: A vertical shaft houses a helical ribbon that lifts material along the chamber walls while gravity draws it downward, ensuring complete mixing.

- ✅ Counterflow Blending Action: Continuous movement from bottom to top and back creates uniform circulation and prevents dead zones.

- ✅ Conical Mixing Chamber: The tapered shape guides materials toward the discharge valve and supports smooth, complete evacuation.

- ✅ Gentle Yet Effective Mixing: Low-shear motion protects delicate ingredients and ensures even blending of sensitive powders and granules.

🔹 Key Components of a Vertical Ribbon Mixer

- ✅ Helical Ribbon Agitator: Promotes effective counterflow mixing and ensures fast, uniform blending.

- ✅ Vertical Conical Mixing Chamber: Upright design supports efficient product flow and easy discharge.

- ✅ Heavy-Duty Drive System: Powerful motor with variable speed capability for adapting to different material needs.

- ✅ Discharge Valve: Located at the cone’s base for complete material removal; available as slide gates, butterfly valves, and more.

- ✅ Optional Custom Features: Temperature control jackets, vacuum integration, and CIP systems for sanitation and process flexibility.

🔹 Applications of Vertical Ribbon Mixers

- ✅ Pharmaceuticals: Accurate and hygienic powder mixing for tablets and capsules.

- ✅ Food & Beverage: Blending of spices, nutritional powders, and food ingredients.

- ✅ Nutraceuticals: Uniform mixing of dietary supplements, herbal blends, and extracts.

- ✅ Chemical Processing: Precise mixing of pigments, polymers, and specialty chemicals.

🔹 Advantages of a Vertical Ribbon Mixer

- ✅ Space-Saving Configuration: Vertical design is ideal for operations with limited floor space.

- ✅ Gentle, Low-Shear Mixing: Protects ingredient integrity during blending.

- ✅ Full Discharge Capability: Conical shape ensures minimal product waste and easy cleaning.

- ✅ Sanitary & Easy to Maintain: Available with polished finishes and CIP-ready designs.

- ✅ Tailored Configurations: Offered in 304SS, 316SS, Hastelloy, and other materials for demanding environments.

🔹 Why Choose PerMix Vertical Ribbon Mixers?

PerMix specializes in high-performance vertical ribbon mixers engineered for precision, consistency, and reliability. With scalable designs, advanced customization options, and durable construction, our mixers deliver optimal results for a wide range of industrial mixing applications.

Upgrade Your Mixing Process with PerMix

Contact our team today to find a vertical ribbon mixer solution tailored to your specific process and production needs!

Advantages of Using a Vertical Ribbon Mixer Under Vacuum

🔹 Advantages of Using a Vertical Ribbon Mixer Under Vacuum

- ✅ Improved Mixing Consistency: Vacuum conditions eliminate trapped air, enhancing homogeneity in powder and paste blending across pharmaceuticals, food, and specialty chemical sectors.

- ✅ Enhanced Product Quality: Reduces air entrapment, improving texture and structural integrity—critical for tablet compression, coatings, and emulsions.

- ✅ Oxidation Control: Vacuum mixing protects sensitive ingredients by limiting oxygen exposure, ideal for nutraceuticals and oxygen-reactive compounds.

- ✅ Better Powder Handling: Mixing under vacuum minimizes clumping and improves flow characteristics, key for accurate dosing in pharmaceutical and powder mixer pharmaceutical operations.

- ✅ Faster Cycle Times: Vacuum-assisted vertical mixers speed up batch processing and improve dispersion, boosting throughput and reducing energy consumption.

- ✅ Cleaner Processing Environment: The closed, vacuum-sealed chamber helps reduce airborne contamination—vital for industries requiring sanitary or cGMP-compliant equipment.

- ✅ Energy Efficiency: Reduced air resistance inside the mixing vessel leads to smoother agitation and potentially lower power demands over time.

- ✅ Flexible Atmosphere Control: Customizable vacuum levels allow for gentle drying, blending, or reaction under controlled conditions—ideal for powder mixers industrial and vacuum dryer applications.

- ✅ Efficient Discharge: Improved material flow minimizes residue buildup and streamlines transfer, especially with sticky or cohesive materials handled in vacuum mixing systems.

Vacuum-integrated vertical ribbon mixers offer clear performance and product-quality benefits across high-precision industries. Whether you’re working with delicate powders, granules, or moisture-sensitive materials, PerMix provides tailored vacuum mixer solutions to meet your exact needs.

Ready to enhance your blending efficiency? Contact PerMix today to learn how our vacuum vertical ribbon mixers can elevate your process.

PerMix Ribbon Mixers with Cantilever Design: Leading the Industry in Cleaning and Maintenance

🔹 PerMix Ribbon Mixers with Cantilever Design: Engineered for Easy Cleaning & Maintenance

PerMix’s cantilever ribbon mixers are designed to meet the highest standards in hygiene, efficiency, and ease of maintenance. This innovative industrial mixer design enhances cleaning access and reduces downtime, making it ideal for industries that demand frequent product changeovers and superior sanitation, such as food, pharmaceuticals, nutraceuticals, and specialty chemicals.

🔹 What Is a Cantilever Design?

A cantilever design supports the mixing shaft from only one side, leaving the opposite end of the mixing chamber completely open. This configuration allows for unobstructed access inside the ribbon mixer, streamlining maintenance, cleaning, and ribbon removal—without requiring disassembly of support structures.

🔹 Key Advantages of the PerMix Cantilever Ribbon Mixer

- ✅ Full Chamber Access: The entire end cover opens for easy access to ribbons and inner surfaces—no special tools needed.

- ✅ Quick Ribbon Removal: The shaft and agitator can be removed swiftly for inspection or sanitation, minimizing cleaning effort and ensuring zero cross-contamination.

- ✅ Hygienic Construction: Polished, crevice-free surfaces prevent material buildup, meeting cGMP and food safety standards for sanitary mixing.

- ✅ Reduced Downtime: Maintenance and cleaning take a fraction of the time, allowing faster changeovers between batches or formulations.

- ✅ CIP-Ready Design: Available with optional Clean-In-Place (CIP) systems for automated sanitation—ideal for allergen-sensitive, pharmaceutical, or nutraceutical production lines.

🔹 Additional Engineering Features

- ✅ Efficient Discharge: The cantilever layout ensures full product evacuation, reducing material waste and simplifying post-process cleaning.

- ✅ Material Options: Constructed in 304SS, 316SS, Hardox, or Hastelloy depending on chemical compatibility or abrasion resistance needs.

- ✅ Customizable Features: Can be configured with vacuum mixing, heating/cooling jackets, powder induction system, and explosion-proof (ATEX/EXP) components.

🔹 Industries That Benefit from Cantilever Ribbon Mixers

- ✅ Pharmaceuticals: Ideal for powder mixer pharmaceutical applications requiring high-purity environments and fast batch turnover.

- ✅ Food & Beverage: Ensures hygienic blending of sensitive or allergen-containing ingredients.

- ✅ Nutraceuticals: Facilitates quick cleaning between vitamin, herbal, or dietary supplement formulations.

- ✅ Chemical Processing: Handles abrasive, sticky, or corrosive compounds with minimal maintenance effort.

🔹 Why Choose PerMix Cantilever Ribbon Mixers?

- ✅ Innovative Engineering: Designed with the operator in mind for fast cleaning and streamlined operation.

- ✅ Custom Built to Your Needs: From vacuum mixers to powder mixers industrial, every unit is tailored to your exact application.

- ✅ Trusted Worldwide: Used in production facilities across the globe for consistent, high-efficiency mixing results.

Looking to reduce downtime and boost sanitation in your mixing process? Contact PerMix today and explore how our cantilever ribbon mixers can transform your blending operations.

PerMix Ribbon Mixer w/ Integrated Bulk Bag Filling

🔹 PerMix Ribbon Mixers with Integrated Bulk Bag Fillers: Efficiency Meets Innovation

PerMix combines advanced ribbon mixer technology with bulk bag filling systems to deliver an all-in-one material handling solution. These integrated units are designed to improve workflow, reduce operational costs, and maximize productivity in food, chemical, pharmaceutical, and industrial blending environments.

🔹 Why Choose Ribbon Mixers with Bulk Bag Fillers?

- ✅ High-Efficiency Mixing: Achieve consistent, homogenous blends for powders, granules, and light pastes with PerMix’s precision-engineered ribbon agitators.

- ✅ Seamless Bulk Bag Integration: Eliminate separate transfer equipment—materials flow directly from the mixer to the bulk bag with minimal dust or spillage.

- ✅ Hygienic Construction: Built with 304SS or 316SS for sanitary compliance in food and pharmaceutical applications. Easy-to-clean surfaces support fast changeovers.

- ✅ Custom Options Available: Add load cells for accurate weighing, automation via PLC/HMI, or dust containment features to suit your application needs.

- ✅ Compact & Cost-Saving: Combine two critical operations—mixing and packaging—into one efficient, space-saving unit to reduce labor and equipment overhead.

🔹 Applications Across Key Industries

- ✅ Food & Beverage: Mix and package flour, spice blends, plant proteins, and functional powders with precision.

- ✅ Pharmaceuticals & Nutraceuticals: Blend fine powders for supplements, then transfer directly to bulk bags for downstream processing.

- ✅ Chemicals & Additives: Ensure uniform dispersion of polymers, pigments, and specialty chemicals in a clean, controlled environment.

🔹 Advanced Features & Design Benefits

- ✅ Integrated Bulk Bag Filling System: Designed for easy docking, filling, and sealing with minimal dust generation.

- ✅ Compact Footprint: Ideal for manufacturers needing efficient equipment layouts with limited space.

- ✅ Fast Maintenance: Quick-disconnect assemblies and open-access design simplify cleaning and inspection.

- ✅ Smart Control Options: Available with programmable automation for consistent, repeatable batch results.

🔹 Customizable to Your Process Needs

- ✅ Heating/cooling jackets for temperature-sensitive powders and granules.

- ✅ Vacuum mixer integration for low-moisture or oxygen-sensitive materials.

- ✅ High-shear choppers for breaking down clumps and enhancing dispersion.

Whether you need a powder mixer for industrial bakery use or a ribbon mixer machine with bulk discharge for chemical packaging, PerMix offers scalable solutions tailored to your production line.

🔹 The PerMix Advantage

- ✅ Trusted Globally: PerMix ribbon mixers are in use worldwide across high-volume production facilities.

- ✅ Proven Durability: Engineered with industrial-grade components for long-term performance and reliability.

- ✅ Versatile Engineering: From industrial mixers to fully automated powder mixer machines, PerMix adapts to your specific needs.

Ready to optimize your mixing and packaging workflow? Contact PerMix today to discover how our ribbon mixers with integrated bulk bag fillers can streamline your operations and deliver lasting performance.

PerMix Ribbon Mixers with Stub Shaft Design: Simplifying Cleaning and Maintenance

🔹 PerMix Ribbon Mixers with Stub Shaft Design: Simplifying Cleaning and Maintenance

PerMix continues to lead the way in industrial mixing technology with our ribbon mixers featuring an innovative stub shaft design. This smart engineering solution enhances sanitation, simplifies maintenance, and improves overall mixing efficiency—ideal for industries where cleanliness and performance are critical.

🔹 What Is a Stub Shaft Design?

The stub shaft design eliminates the need for a full-length central shaft, allowing unobstructed access to the mixing chamber. Supported at both ends, the ribbon shaft is securely anchored while enabling easy access for cleaning and disassembly—perfect for ribbon mixers used in sanitary and high-performance applications.

🔹 Benefits of the Stub Shaft in Industrial Mixers

- ✅ Unmatched Cleaning Access: No center shaft means every interior surface is easy to reach and clean thoroughly.

- ✅ Simplified Maintenance: Quick-disconnect ribbon assembly allows for fast disassembly without special tools, minimizing downtime.

- ✅ Sanitary Operation: Smooth, crevice-free design helps eliminate buildup, supporting GMP and hygienic standards.

- ✅ Reduced Risk of Contamination: Efficient product discharge reduces residue and supports allergen control and batch separation.

- ✅ High Durability: Stub shafts are built to handle abrasive, corrosive, and high-viscosity materials with consistent performance.

🔹 Ideal for a Wide Range of Industries

- ✅ Pharmaceuticals: Ensures clean changeovers between batches for compliance and product purity.

- ✅ Food & Beverage: Supports allergen control and hygiene with easy-to-clean mixing equipment.

- ✅ Nutraceuticals: Maintains blend quality and simplifies sanitation for powder and supplement mixing.

- ✅ Chemicals: Handles corrosive or abrasive compounds with minimal wear and easy upkeep.

🔹 Key Features of PerMix Ribbon Mixers with Stub Shaft Design

- ✅ Quick-Release Shaft Assemblies: Enable rapid ribbon removal for maintenance or cleaning.

- ✅ Customizable Construction: Choose from 304SS, 316SS, Hardox, or Hastelloy to meet material handling needs.

- ✅ Hygienic Finishes: Polished internal surfaces with optional CIP (Clean-In-Place) compatibility.

- ✅ Process Integration: Available with heating and cooling jackets, vacuum drying, or ATEX-rated explosion-proof configurations.

🔹 Why Choose PerMix?

- ✅ Engineered for Innovation: The stub shaft system is one of many forward-thinking features found in PerMix powder mixers.

- ✅ User-Friendly Design: Save time and labor with easy access and tool-free maintenance.

- ✅ Industry-Centric Customization: PerMix industrial mixers are tailored to match your exact application and compliance needs.

- ✅ Trusted Worldwide: PerMix mixing equipment is relied on globally by leaders in pharmaceutical, food, and chemical industries.

Streamline your mixing process with a hygienic, efficient solution. Contact PerMix today to learn how our ribbon mixers with stub shaft design can enhance your production line while meeting the highest standards of cleanliness and reliability.

Metal Thickness, Strenght, & Torque Transfer...PerMix Leads By Example

🔹 Built to Last: Why PerMix Mixers Stand Above the Competition

At PerMix, our commitment to quality starts with the structure. Unlike many industrial mixer manufacturers that cut corners to save on material costs, we engineer our mixing equipment with thicker stainless steel—ensuring long-term performance and unmatched durability.

While some competitors rely on thinner metals and structural bending to simulate strength, these shortcuts create stress points that are prone to fatigue and cracking over time. At PerMix, we do it differently—and better.

- ✅ Thicker Metal Construction: Delivers true structural integrity for demanding industrial applications.

- ✅ Optimized Torque Transfer: Handles higher power loads from the motor and gearbox with ease.

- ✅ No Bend Reliance: Reduces weak spots, minimizing maintenance and maximizing operational lifespan.

- ✅ Heavy-Duty Performance: Designed to run efficiently under tough mixing conditions with fewer breakdowns.

We never compromise on quality. Whether you’re investing in a ribbon mixer, industrial blender, or other industrial mixing equipment, choosing PerMix means choosing a system that’s built to last.

Don’t settle for less. Choose strength. Choose PerMix.

💡 Have questions about mixing system design or durability? Contact us today to see how PerMix can elevate your process with engineering that goes the distance.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.