Industrial Mixers

PerMix Fluidized Zone Mixer

PerMix Fluidized Zone Mixer for Fast, Homogeneous Powder Mixing

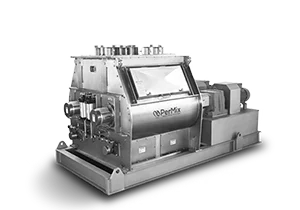

The PerMix Fluidized Bed Mixer, also known as a Twin Shaft Paddle Mixer, delivers rapid and efficient mixing through a fluidizing action. Commonly referred to as a fluidizing mixer, zero-gravity mixer, or non-gravity mixer, it’s designed for high-speed blending with minimal energy input.

PerMix Dual Shaft Fluidized Zone Mixer Introduction

The Fluidized Bed Mixer, also known as a Twin Shaft Paddle Mixer, is engineered to produce uniform mixtures regardless of particle size, shape, or density. Ideal for adding small quantities of powders or liquids into bulk materials, it ensures fast, precise, and high-capacity mixing.

How Dual Shaft Fluidized Zone Mixer Works

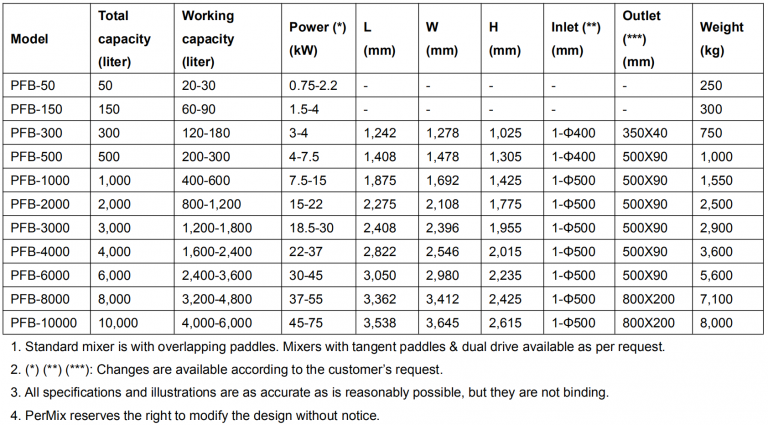

The PerMix PFB series Fluidized Bed Mixer, also known as a Twin Shaft Paddle Mixer or Non-gravity Mixer, is engineered for rapid and uniform blending of powders and granules. It features specially angled paddles mounted on twin shafts inside a W-shaped trough. These shafts rotate in opposite directions to generate a fluidized, weightless mixing zone.

As the paddles rotate, they sweep across the troughs and lift the materials into a zero-gravity state. In this suspended zone, particles—regardless of size, shape, or density—move freely and mix efficiently. This dynamic action ensures fast, homogeneous blending, even for challenging formulations with varying bulk properties.

Dual Shaft Fluidized Zone Mixer Features & Advantages

- Rapid Mixing Performance: Designed for speed, the twin shaft mixer can deliver thorough blending in just 10 seconds to 1 minute—ideal for high-throughput operations.

- Optimized Particle Flow: Unrestricted material movement ensures uniform distribution, supporting precision in even the most sensitive mixing tasks.

- Gentle, Low Shear Action: The twin shaft paddle mixer provides smooth motion that protects fragile ingredients—perfect for heat- and shear-sensitive materials.

- Hygienic, Easy-to-Clean Design: Built with minimal blind corners for fast cleanup, this powder mixer supports strict sanitary standards across industries.

- Minimal Maintenance Needs: Reliable, low-complexity engineering reduces wear and tear, ensuring long-term uptime for your mixing equipment.

- Quick & Clean Discharge: A large bomb-bay style door allows for rapid product release and minimizes material separation.

- Seamless Liquid Integration: Compatible with spray nozzles, drip pipes, or spray balls, making it ideal for systems requiring a powder induction system.

- Durable Paddle Options: Paddle blades can be customized or reinforced, supporting demanding paddle mixer applications with heavy-duty loads.

- Integrated Lump Breakers: Optional choppers provide extra power to break down clumps and ensure a consistent blend.

- Versatile Drive Configurations: Choose from single or dual motor systems to suit your plant’s specific mixer needs.

Dual Shaft Fluidized Zone Mixer Applications

a. Chemical Industry

PerMix industrial mixers handle a wide range of chemical products like detergents, pigments, fertilizers, boric acid, soda ash, carbon, fly ash, fungicides, and explosives with precision and safety.

b. Building Industry

Our powder mixers are ideal for dry mortar, blended cements, tile adhesives, cement-fiber blends, flooring materials, and joint compounds, offering reliable performance in rugged environments.

c. Environmental Applications

For fly ash conditioning, filter dust treatment, sewage sludge, and food waste, PerMix mixing equipment ensures efficient, continuous processing with minimal maintenance.

d. Feed Industry

From mineral premixes to fish feed and pet food, our paddle mixers deliver fast, uniform blending for all types of animal nutrition.

e. Food Industry

Designed for hygiene and efficiency, PerMix industrial mixers are perfect for soups, infant milk, bakery mixes, spices, and frozen vegetables.

f. Pharmaceutical Industry

PerMix mixers meet strict pharma standards, providing consistent results for vitamin blends and medical powders with options like vacuum mixers and double cone mixers.

PerMix Single Shaft Fluidized Zone Mixer Introduction

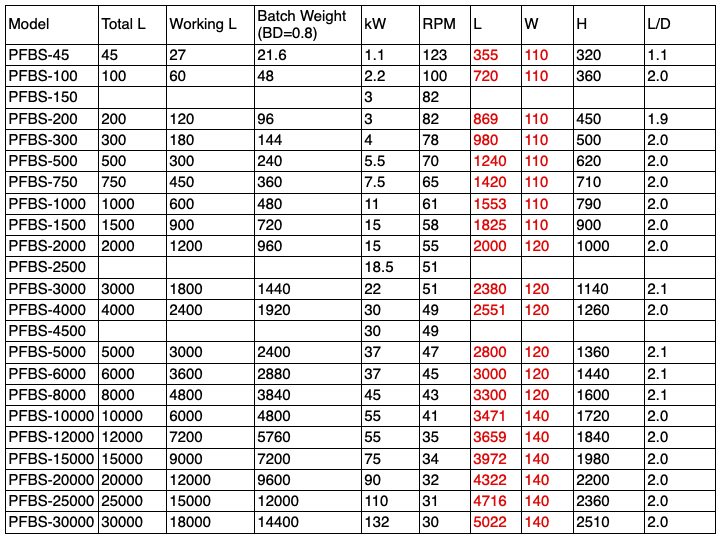

The PerMix Single Shaft Fluidized Zone Mixer, like its Twin Shaft Fluidizing Zone Mixer, is a high-efficiency, low-shear solution ideal for rapid and uniform mixing. Often referred to as a fluidizing mixer, non-gravity mixer, or fluidizing paddle mixer, it’s designed for precise and consistent results.

This advanced paddle mixer creates a fluidized mixing zone that enables free movement of particles, regardless of size, shape, or density. Whether you’re adding trace amounts of powders or liquids into bulk material, the fluidized bed mixer—available in both single and twin shaft configurations—delivers fast, high-capacity blending with exceptional accuracy.

How Single Shaft Fluidized Zone Mixer Works

The PerMix PFB and PFBS series Fluidized Bed Mixers—available as Single or Twin Shaft Paddle Mixers—are advanced non-gravity mixers designed for high-speed, high-efficiency blending. Built with paddles mounted at precise angles inside a U- or W-shaped trough, these mixers create an optimal flow pattern during operation.

As the shafts rotate—counter-rotating in twin-shaft configurations—they sweep the entire trough bottom. The paddles generate centrifugal force, lifting materials into a fluidized, weightless zone. In this zone, particles move freely and randomly, allowing for fast, uniform mixing regardless of differences in density, shape, or size. The result is rapid, highly homogeneous blending across a wide range of materials.

Single Shaft Fluidized Zone Mixer Advantages & Features

- Fast Mixing Performance: Delivers efficient blending in just 10 seconds to 1 minute, ideal for high-throughput operations.

- Free Particle Movement: Materials flow freely within the mixer, ensuring consistent results across various particle sizes and densities.

- Low Shear, Low Heat: The twin shaft paddle mixer operates with minimal friction, protecting heat-sensitive and fragile materials—even flakes and spray-dried powders stay intact.

- Hygienic & Easy to Clean: Designed with minimal blind corners for quick cleaning and sanitary operation.

- Low Maintenance: Simplified design reduces downtime and ensures reliable, long-term performance.

- Efficient Discharge: Large bomb-bay doors allow for fast emptying and reduced product segregation.

- Liquid Addition Options: Supports spray balls, nozzles, or drip systems for accurate and uniform liquid dosing.

- Wear-Resistant Paddle Edges: Ribbon and paddle edges can be coated with Tungsten Carbide for use with abrasive materials.

- Optional High-Speed Choppers: Integrated choppers break down lumps and improve blend uniformity.

- Flexible Drive Systems: Available with single motor/gearbox with chain, dual motor/gearbox, or single motor with dual gearbox configurations.

Need Help Selecting Your Equipment?

Talk to our product expert today

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.