Industrial Mixers

PerMix News & Updates

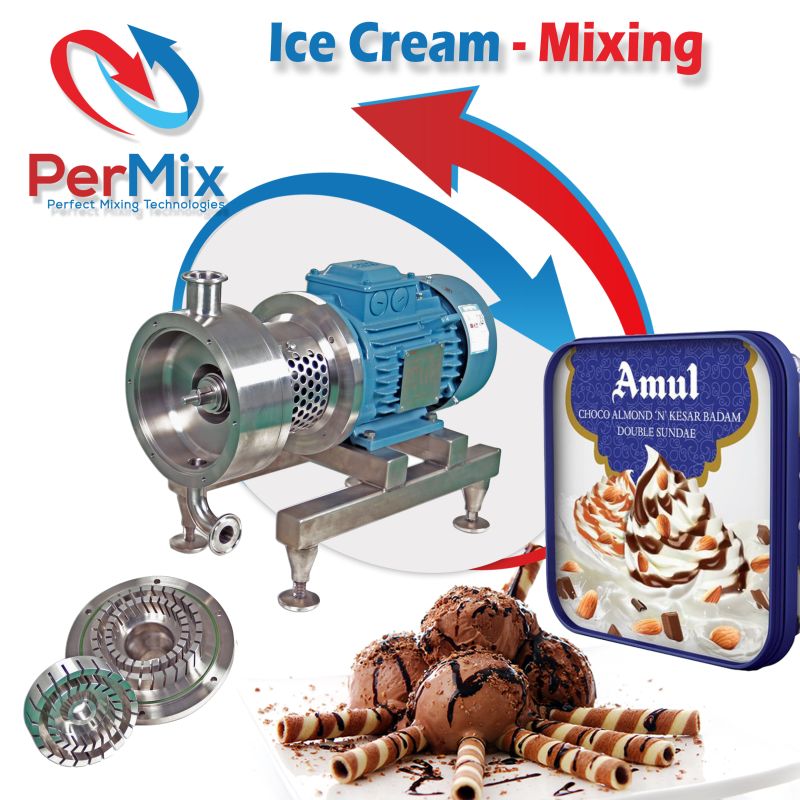

How to prepare Ice-Cream with the help of Inline Mixers?

Generally Ice cream contains ingredients such as milk solids, sucrose, milk fats, syrups, stabilizers, emulsifiers, and water. Although stabilizers and emulsifiers are less in proportion they play a major role in the formation of ice cream. Stabilizers are used to prevent the growth of the ice crystals during storage, to provide the required mouth feel, etc. Emulsifiers are used to ensure that fat in ice cream is dispersed uniformly.

The stabilizers generally used in the ice cream are guar, cellulose gum, locust bean, and xanthan. Other stabilizers such as acacia, agar, and pectin are also used but less frequently. Emulsifiers used in the process include lactic acid, mono di-glycerides, propylene glycol esters, and blends of these.

Some of the hurdles faced during the mixing of the stabilizers and emulsifiers are long processing times required for complete dispersion, the addition of powders must be at a uniform rate to reduce agglomerates, Cleaning cycles are required frequently which leads to downtime and increase in cost, orthodox systems are not capable to produce sufficient shear to break agglomerates down.

PerMix offers Inline Mixers to address this challenge. The ingredients are rapidly introduced into the mixer and are dispersed throughout. The agglomerate formation is taken care of as stabilizers & emulsifiers are broken down. Due to the high speed of the rotor, materials are sucked in and they experience an intense shear in the rotor-stator assembly. After this, the product is discharged and again new materials are drawn in thus continuing the entire process.

A few of the benefits of the inline mixer are that it mixes rapidly, the mix produced is free of agglomeration, and premixing of the ingredients is not required. There are several more advantages, for more information contact us

#permix#mixers#blenders#engineering #innovation #foodmanufacturing